HDPE Pre-insulated Pipe Casing Extrusion Line

I. Product Introduction

The HDPE pre-insulated pipe casing extrusion line is a highly efficient and energy-saving device used for manufacturing HDPE pipes that serve as protective covers for polyurethane (PU) foam thermal pre-insulated pipes in accordance with international standards. The HDPE casing pipes produced by this line are made using the vacuum calibrating method, which ensures smooth internal and external walls, long service life, excellent anti-corrosion insulation, and good mechanical performance.

II. Product Parameters

| Model |

PE-110/500 |

PE-655/1380 |

PE-960/1860 |

PE-1155/2200 |

| Main Extruder Model |

SJ-75/33 |

SJ-120/33 |

SJ-150/33 |

SJ-150/33 |

| Pipe Diameter Range (mm) |

Φ110-600 |

Φ655-1380 |

Φ960-1860 |

Φ1155-2200 |

| Capacity (kg/h) |

250-350 |

700-900 |

1000-1200 |

1350 |

| Installed Power (kw) |

160 |

480 |

580 |

650 |

| Length (m) |

26 |

36 |

45 |

45 |

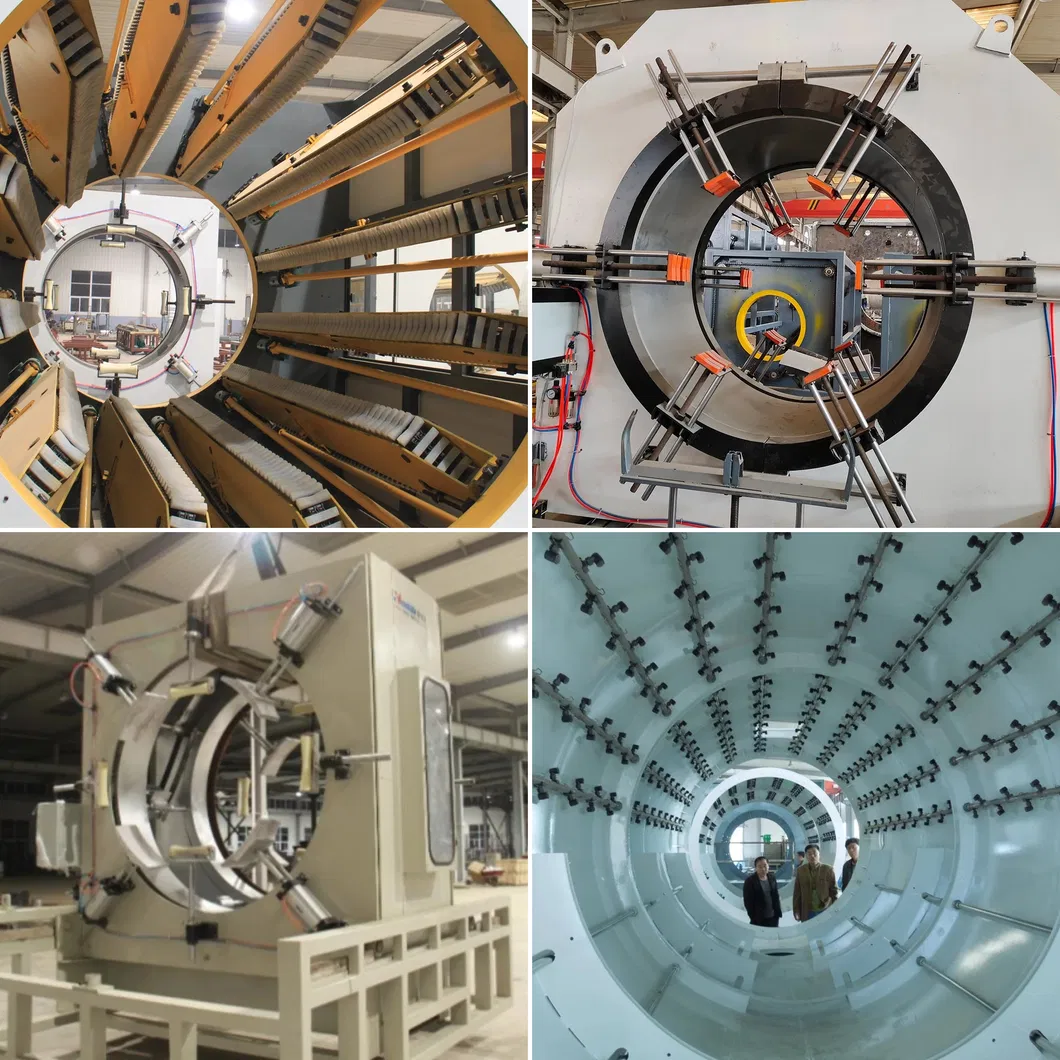

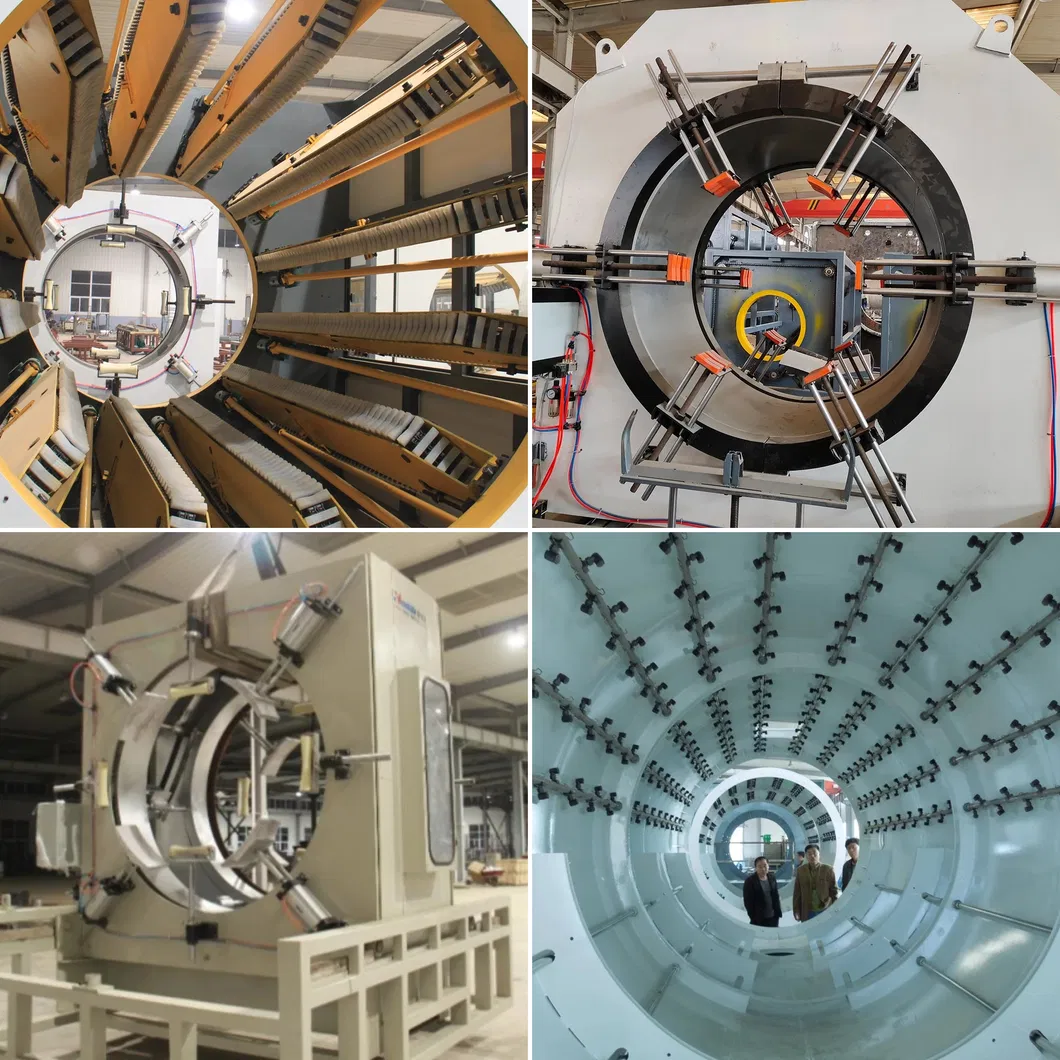

III. Production Line Composition

1 set of Vacuum Loader

1 set of Hopper Dryer

1 set of High-efficiency Single Screw Extruder

1 set of Vacuum Calibration Table

1 set of Water Spraying Tank

1 set of Hauling Machine

1 set of Cutting Machine

1 set of Discharging Frame

IV. Our Advantages

A. Features of the Production Line

√ Compact size

√ High degree of automation, allowing operation by a single person to save labor costs

√ Long service life

√ High-efficiency extruder provides high output and stable performance

√ Uniform and smooth pipe wall

√ No waste of raw materials

√ One-time forming, eliminating the need for trimming edges

B. Service Advantages

√ Provide a complete production solution: design, installation, commissioning, and training

√ Share extensive experience from 389 sets of production lines worldwide

√ Employ 9 professional senior engineers

√ Possess a high-end plastic machinery expert workstation in China

V. HDPE Jacket Process Flow

Vacuum feeding of PE granules → Hot air drying of material → Extrusion plasticizing → Mold shaping → Vacuum sizing → Water cooling → Pulling out → Cutting pipe → Carrier laying-off pipe

VI. Applications

The HDPE pre-insulated pipe extrusion line is widely used to produce protective jackets for thermal insulated pipes in various industries, including:

√ District Heating Systems

√ Hot and Chilled Water Piping Systems

√ Gas Pipelines

√ Water Mains

√ Geothermal Heating Systems

Company Profile

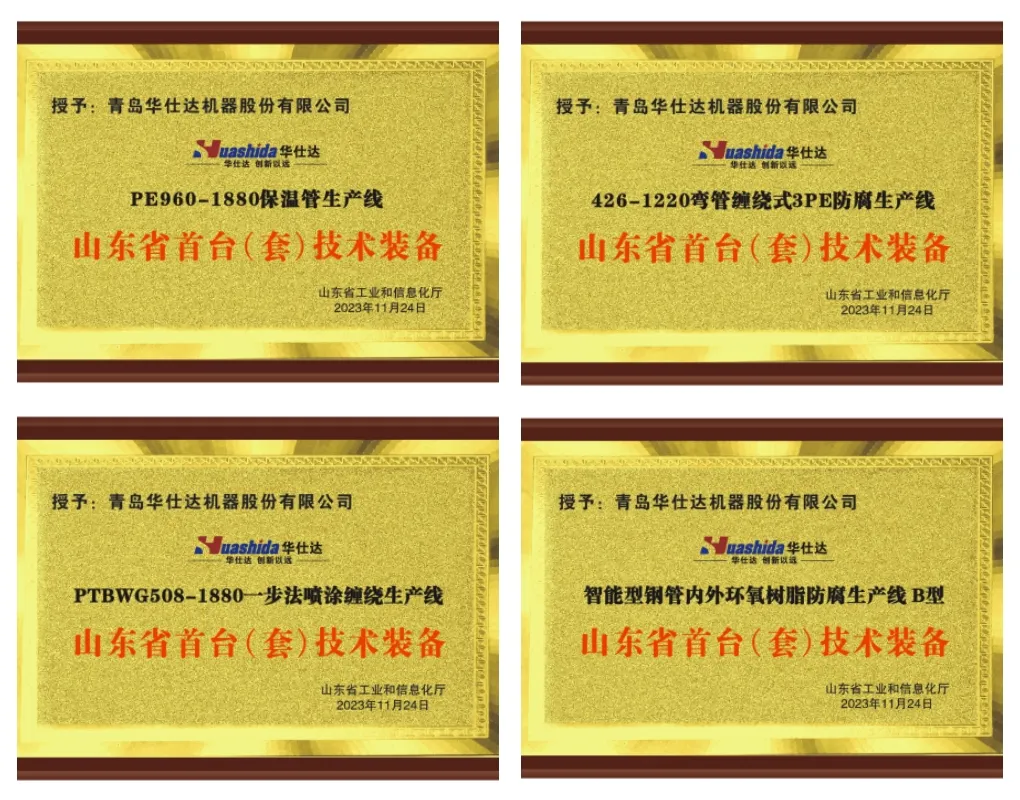

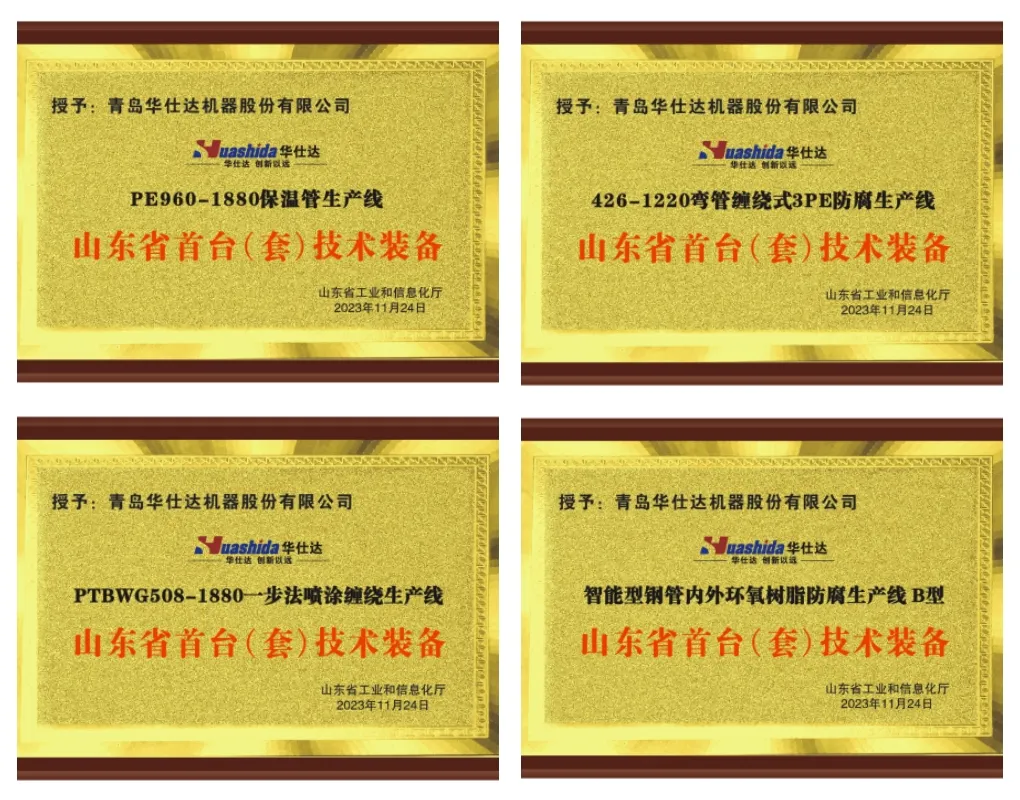

Qingdao Huashida Machinery Co., Ltd. has been engaged in the development and producing of pipeline anti-corrosion equipment and raw materials since 2003. It is a leader manufacturer of heat-shrinkable sleeve and equipment in China. Huashida brand is favored by domestic and foreign customers. Devices of the equipment design have our patents. We passed ISO9001, ISO14001Environment, ISO45001 health certification. Up to now, more than 500 sets of production lines have been exported to Russia, Kazakhstan, Belarus, Egypt, Iran, Indonesia and other countries. Huashida brand heat shrinkable sleeve equipment in the production process of continuous summary and update has launched the fourth generation of products. The whole production line has reasonable design, intelligent operation, high speed and high efficiency, energy saving and electricity saving material labor cost. Continuous improvement in component design ensures uniform thickness, improved shrinkage, tensile strength and elongation at break. Product quality to meet the needs of different pipeline anti-corrosion demand. We have a professional after-sales service team to provide on-site and online video teaching and training. Help customers solve production problems as soon as possible.

Our Team

Certifications

International Trading show

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!